Bag Sewing

For more than a century, packaging companies of every size and from every industry, have trusted Fischbein to provide the most efficient, most dependable machinery for closing all types of filled bags. We manufacture a full range of innovative bag sewing equipment, from our line of hand-held portables to our high-speed bag sewing systems…A new level of excellence in bag sewing technology. Also available from Fischbein are a wide variety of accessories including bag-top folders, taggers, thread or tape break detectors and a full range of conveyors. Whether your application calls for plain sew or sew through tape or uses multi-wall paper bags or woven polypropylene, nett or jute bags, Fischbein has engineered a solution that will meet your needs.

Portable F

Description

The portable F is a new level of excellence in sewing technology. Its robust design works with ease on the bagging line or in the field and its durable non-corrosive epoxy finish will make it last for years.

It is a 1-thread sewing machine to close all types of bags: paper (single or multi-wall), woven or unwoven polypropylene, nett, polyethylene, burlap, cotton bags of any content.

Advantage(s)

- Fast

- Safe

- Low cost maintenance

- Fischbein double insulated motor

- Semi-automatic lubrication

- Presser foot lifter mechanism

Mini-system FTS

Description

The mini-system is perfect for small bagging operations that require up to 300 sewn bags per hour

The mini-system FTS is used to close, by plain sewing, all types of bags (paper, polypropylene, or polyethylene) by plain sewing. The already reshaped bag is introduced into the infeed which guides the bag to the sewing machine. The sewing process starts when the feeler switch is activated. At the end, the pneumatic chain pusher pushes the chain into the knives to cut it. To have a smooth operation of the mini system a conveyor is required. The conveyor can be controlled by a footswitch.

The mini-system FTS operates automatically for small outputs up to 250-300 bags/hour.

Other models of mini-systems are available.

Sewing Head 100

Description

Built with the world-famous Fischbein craftmanship, the Sewing Head 100 is constructed with heavy-duty metal components for unmatched durability you can rely on for years to come. Even in the most demanding working environments, Fischbein’s pressurized, self-lubrication system protects moving parts and ensures maximum productivity with low maintenance.

The Sewing Head 100 is a “low vibration" sewing head, used for tape and/or plain sewing of open-mouth bags, including paper, polyethylene (min. 120 microns), coated woven polypropylene and complex bags. Sewing head requires to be mounted on an appropriate column or frame (see ""Fischbein"" sewing systems).

The Sewing Head 100 operates with an easily adjustable sewing speed from 8 to 23,8m/min

Advantage(s)

• Self-lubrication of moving parts

• Exceptional reliability

• Low vibration

• Easy functioning

Sewing Head 101

Description

Built with the world-famous Fischbein craftmanship, the Sewing Head 101 is constructed with heavy-duty metal components for unmatched durability you can rely on for years to come. Even in the most demanding working environments, Fischbein’s pressurized, self-lubrication system protects moving parts and ensures maximum productivity with low maintenance.

The Sewing Head 101 is a low vibration" sewing head, used for tape and/or plain sewing of open-mouth bags, including paper, polyethylene (min. 120 microns), coated woven polypropylene and complex bags. Sewing head requires to be mounted on an appropriate column or frame (see "Fischbein" sewing systems).

The Sewing Head 101 operates with an easily adjustable sewing speed from 8 to 21,9m/min

Advantage(s)

• Self-lubrication of moving parts

• Exceptional reliability

• Low vibration

• Easy functioning

Sewing Head 200

Description

Fast and powerful for smooth performance with low vibration, the Sewing Head 200 is specially designed to meet the requirements of high production. Regardless of how though the working environment is, Fischbein’s heavy duty precision components will give you years of dependable performance.

The Sewing Head 200 is a high speed sewing head used for plain sewing of every type of open-mouth bags, including paper, woven polypropylene, jute, burlap. Specially suited for nett bags. Typical application for this sewing head: potatoes packing line. The Sewing head requires to be mounted on an appropriate frame (see "Fischbein" sewing systems) and the mandatory use of a fan specially designed to cool the unit during operation (not delivered with the unit).

Built with traditional Fischbein craftmanship, the Sewing Head 200 features a pressurized, self-lubrication system which protects moving parts from dust and particles, ensuring maximum productivity and low maintenance.

The sewing head 200 features a linear sewing speed that is adjustable up to 29,9m/min

Advantage(s)

• Designed for high production and high speeds

• Self-lubrication of moving parts

• Exceptional reliability

• Easy maintenance

Sewing Head 201

Description

Fast and powerful for smooth performance with low vibration, the Sewing Head 201 is specially designed to meet the requirements of high production. Regardless of how though the working environment is, Fischbein’s heavy duty precision components will give you years of dependable performance.

The Sewing Head 201 is a high speed sewing head, used for tape and/or plain sewing of open-mouth bags, made out of paper, polyethylene (min. 120 microns), coated woven polypropylene, and complex bags. The

Sewing head requires to be mounted on an appropriate frame (see "Fischbein" sewing systems) and the mandatory use of a fan specially designed to cool the unit during operation (not delivered with the unit).

Built with traditional Fischbein craftmanship, the Sewing Head 201 features a pressurized, self-lubrication system which protects moving parts from dust and particles, ensuring maximum productivity and low maintenance.

The sewing head 201 features a linear sewing speed that is adjustable up to 28,6m/min

Other models of sewing heads are available: Atex Version, 100 Twin Needle, corrosion resistant…

Advantage(s)

• Designed for high production and high speeds

• Self-lubrication of moving parts

• Exceptional reliability

• Easy maintenance

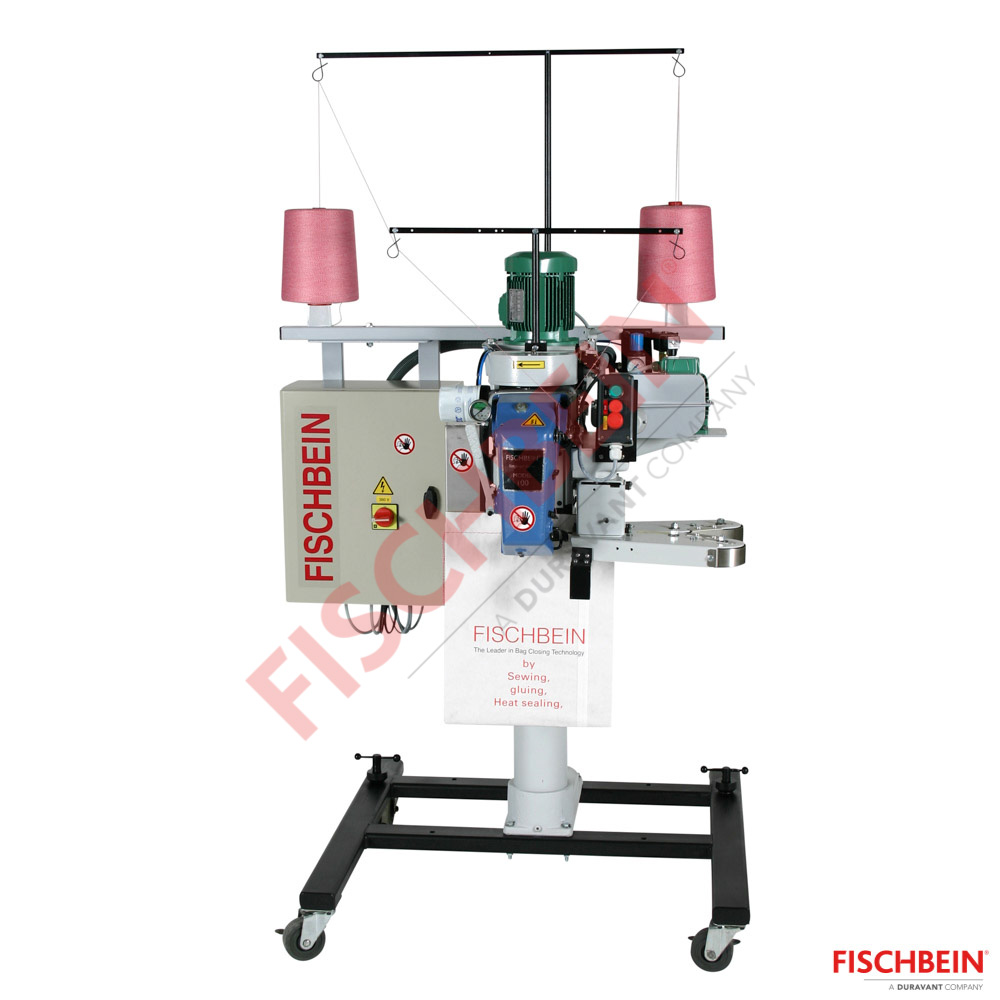

Sewing System MTR

Description

The sewing system offers various industrial features depending on the number of bags to be closed; the manpower, the skill of the operators, the degree of automation, the type of bags…from a manual operation up to a system with infeed for automatic handling.

The sewing system MTR features the world famous Sewing Head 100 and takes advantages of its state-of-the art innovations.

The sewing system MTR is used to close paper, polypropylene, or polyethylene (thickness +/-120 µ) bags. The already reshaped bag is introduced into the infeed which guides the bag to the sewing head. The sewing process starts when the photo sensor detects the bag. At the end the rotary knife cuts the chain. To have a smooth operation of the system, a conveyor is required. The conveyor can be controlled with a footswitch.

Other models of sewing systems are available.